Mary-Cathryn's Response in "15 biz leaders predict effects of the remote work trend"

When the Covid-19 pandemic struck, many businesses were forced to set up remote work arrangements. While some companies have returned to the office, many others intend to retain full or partial remote work arrangements well into the future.

The shift toward telecommuting is bound to change the business landscape in a big way. That’s why we asked 15 members of Business Journals Leadership Trust what they foresee happening as a result of the growing trend toward remote work. Here’s what they believe some of the long-term impacts might be.

1. Expect cross-state tax implications.

Adopting a remote workforce can expand your pool of applicants outside your HQ state. But businesses may not realize they could be expanding their sales tax obligations by doing so. The same could happen for employees who live across state lines and now work fully remotely. States are being lenient for now, but we can expect them to want registrations for the newly added states if this becomes the standard. – Robert Dumas, TaxConnex

2. Remote work may be a catalyst for better diversity, equity, and inclusion.

Remote work can be a catalyst for better diversity, equity, and inclusion in the workplace. Recruiting the best talent — not just the closest — offering flexible scheduling and relying more on results instead of who best navigates office dynamics is a win. A remote model can lead to significant gains in bringing more underrepresented groups to the table. –Natalie Ruiz, AnswerConnect

3. Companies will have the opportunity to earn employee loyalty through flexibility.

Companies that offer more flexibility in terms of working arrangements have the opportunity to earn the loyalty of their employees, who in turn will work more productively and want to contribute more to the company. A negative is the lack of serendipitous connections between co-workers or employees from different divisions who form relationships, which can spur innovative improvements. –Andrew Duffell, Research Park at FAU

4. Businesses will need to incorporate trust-building practices into wellness offerings.

Trust is the foundation of any healthy team, especially those that are remote. On top of the pandemic, political division and civil unrest have left many of us shaken. Incorporating trust-building practices into your wellness offering will help employees feel safe with their colleagues so they can bring their full selves to work, enabling the team to perform at its highest level. – Deni Tato, Corporate Consciousness

5. Corporate culture will be more important than ever.

Pre-Covid-19, partial or full remote working was a differentiating employee benefit. The pandemic leveled that field. Those companies that didn’t offer it before do now, and many of them find employees are happier and, often, more productive. As a result, corporate culture will become more important in attracting and retaining talent, as staff will expect the same level of interaction and professional development as they had onsite. – Daniel Serfaty, Aptima, Inc.

6. Businesses will need to give teams the ability to interact socially.

As businesses embrace remote work they need to remember that people want and need social interaction with their team. It’s important that each team determines what that means to them and that they have the ability to be flexible about when and how those interactions take place. – Laura Doehle, Elevation Business Consulting

7. Remote workforces will escape the ‘speed of paper.’

Escaping the “speed of paper” is a key benefit of embracing a remote workforce. Remote workforces teach teams to produce, share and store content in one effective step. In addition, electronic data is easier to update and easier to analyze or mine for actionable insights. Often, paper content cannot be found or deteriorates and information needs to be re-keyed to perform analysis. – Kirk W. McLaren, Foresight CFO

8. Flexibility will provide a better work-life balance.

I think the flexibility that remote working provides will, in the long run, make the balance between work and personal life better. It will most likely be an employee-by-employee decision on how much if any remote working will take place. –Daniel Wilson, Lacey Thaler Reilly Wilson Architecture & Preservation

9. The quality of work and training may suffer.

On the negative side, I predict two things. The first is poor quality work from those who are not efficient or effective in a remote setting. Second, poor training can arise in difficult remote interactions when accountability for “actual” teaching and learning is not measured clearly enough and competency in a given topic is simply not realized. –Joy Frestedt, Frestedt Incorporated

10. Remote meetings could create a more intimate experience.

There are bursts of productivity because people aren’t commuting or spending as much time in meetings. But many people also struggle with child care, distance learning, isolation or financial worries. Although Zoom can’t replicate in-person meetings, it’s a more intimate experience in some ways. You get a peek into someone’s home office or dining room, and their kids or pets sometimes make cameos. – Mary-Cathryn Kolb, brrrº

11. Maintaining company culture will be a challenge.

Most successful businesses have a distinct culture that defines who they are and how they operate. Maintaining that culture presents new challenges for businesses with remote workers, particularly when they hire new staff members. Leaders would be well-served to think proactively about how they will onboard new team members and instill the company’s values in them in a remote working situation. –Kieran Shanahan, Shanahan Law Group, PLLC

12. Corporate communication will continue to improve.

As we look for silver linings in the benefits of remote work arrangements, we certainly see families having more time together. Surprisingly, corporate communications have improved as we focus on regularly scheduled connection meetings and both personal and professional information shares — “Show and Tell” has gone corporate. What’s missing? The basic human need for socialization. –Brent Maugel, Maugel Architects

13. Companies that haven’t researched labor laws may face consequences.

We’re seeing a lot of risk in labor and employment. There are too many employers out there running remote teams without having gone through a thorough evaluation of how changes in employment law and applicable regulations impact their policies and remote work. Unless this is done, we foresee an avalanche of cases that will cost employers dearly. – Robert Newland, Newland Associates

14. Investment in office real estate will decline.

Increasing acceptance of remote work arrangements devalues traditional office real estate. Logically, investment in traditional office real estate will likely decline relatively, both in existing infrastructure and new construction. –Jason Dunn, CFA, DACS Asphalt & Concrete

15. Businesses may be able to grow more quickly.

Working remotely will reduce overhead costs and allow for considerable growth without having to increase the office footprint. This may save business owners money and allow them to grow more aggressively. –David Wescott, Transblue

Original Article: Biz Journals

brrr° featured in WTiN's Twist magazine

Cooling effects

The Triple Chill Effect fabric technology from brrr° is being used in a growing range of products and the company is planning to enhance the technology through further development of its cooling minerals. Fiona Haran finds out more.

Busy, active lifestyles coupled with the ongoing climate crisis that continues to dominate the headlines are driving the demand for innovative cooling solutions in all aspects of our daily lives. And, as textiles are omnipresent, they naturally make a great vehicle for administering such solutions. Feeling cool and comfortable in whatever activity we’re doing heightens our overall wellbeing and performance. So, with this in mind, the American company brrr°, based in Atlanta, Georgia, set out to explore how textiles can be enhanced to meet this need. Founded in 2014 by Mary-Cathryn Kolb, a retail industry expert who has worked for apparel brands such as Spanx and Von Dutch, brrr° developed a proprietary cooling fabric technology that can be integrated into any existing fabric to bring immediate and continuous cooling. To do so, a secret blend of natural minerals is embedded into the yarn itself to become a permanent part of the fabric that, unlike coatings or sprays, doesn’t wash out over time.

Explaining the process in more detail, Mary Jane Credeur, a spokesperson for brrr°, says: “We begin by adding our secret blend of minerals into the nylon or polyester pellets, which are extruded as yarn that is then turned into fabric. Our cooling minerals are permanent and part of the structure of the yarn. Under a microscope you can actually see the little mineral speckles.” The cooling feature is combined with wicking and rapid drying technology to form what brrr° calls the Triple Chill Effect. For instance, brrr° nylon and brrr° polyester are described as ‘cool to the touch’ with more chill than comparable competitors, according to the company, which adds that the wicking technology moves moisture away from the skin, for ‘non-stop comfort’, and the quick drying capability rapidly releases moisture into the air, cooling the fabric and providing a ‘fresh and crisp’ experience. To realise the potential of the technology, brrr° has several ‘go-to’ mill partners in Taiwan which are considered a part of its R&D team. All brrr° products are tested by independent labs to prove their effectiveness. For instance, tests conducted last year by Intertek found that brrr° nylon and polyester fabrics consistently outperformed numerous other comparable products in lab tests that measure Qmax (cool to the touch feeling), wicking and dry time. “For years, a lot of the apparel manufacturers claimed that their products were cooling but they were just wicking, they didn’t actually draw away heat per se,” says Credeur. “Some products you have to get wet before they cool, and that’s not very practical. The science behind it, that’s our pedigree. It’s not just a gimmick that’s going to wear out over time like sprays or coatings do.”

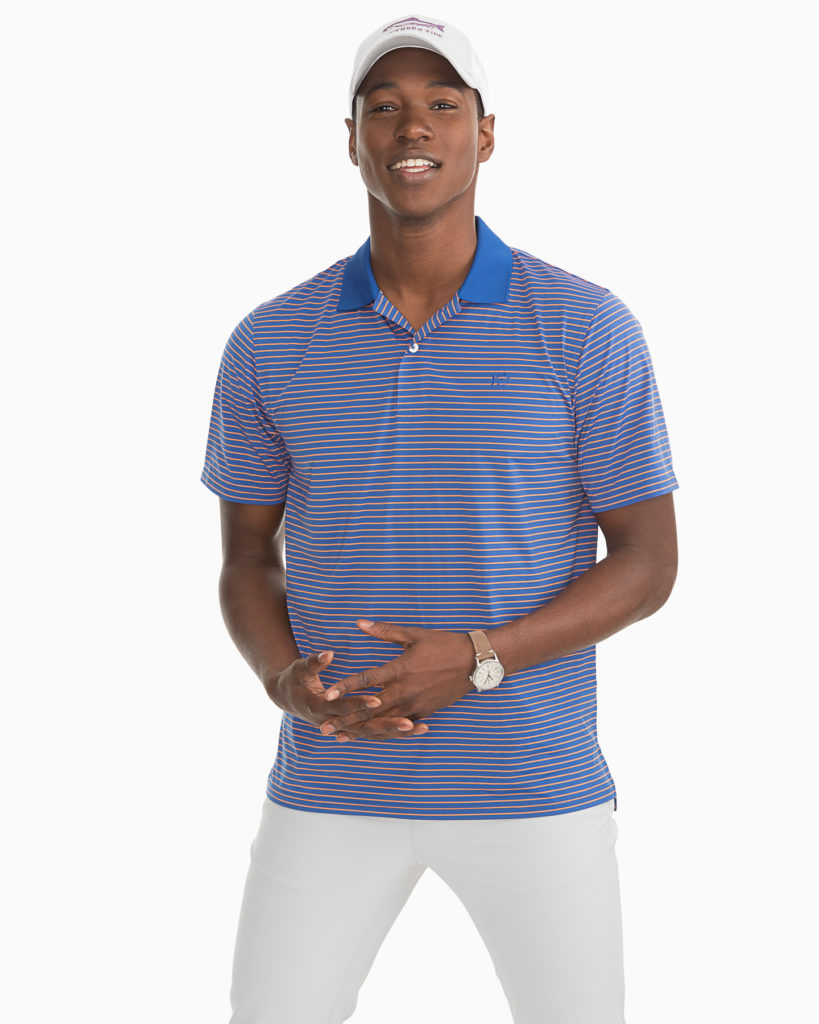

An obvious application for the technology is activewear and outdoor wear, where users are prone to working up a sweat, but the end uses span various elements of a consumer’s wardrobe and lifestyle. And, as an ingredient brand, brrr° has garnered interest from a range of retailers and manufacturers looking to integrate the cooling fabric technology into their collections. Products featuring the technology include women’s blouses from ADAY, performance socks from Bigfoot Sock Co., Bermuda shorts from Coral Coast Clothing, the Guide workout T-shirt from Greyson, technically advanced shirts for commuters from Kit and Ace, men’s blazers from Mizzen+Main, caps and hats from The Game, and a range of casual clothing from Southern Tide, such as women’s dresses and men’s polo shirts. In addition, retailer JoS. A. Bank uses brrr° suit liners. Credeur says: “A lot of our launches have been casual polo shirts, so not just outdoor wear, but also casual weekend wear, office wear, dress shirts, linings of suits, and undergarments. We’re really starting to get traction with national and international retailers, and we’re in talks with a few co-branded partners. Plus, we have a new line launching with CAT Workwear from Caterpillar – an outdoor, rugged apparel line.” Home textiles are another key end use, particularly bed sheets. “There tends to be more demand around things you actually touch and interact with,” says Credeur. “Sheets are an obvious one, as memory foam mattresses make you sweat a little bit more. Women who are menopausal or pre-menopausal tend to appreciate that a lot. We think that someday we’ll get some demand from sofa material coverings and fabric for upholstery. And we have been in talks with auto manufacturers for car seat materials.”

The company has also integrated its cooling fabric technology into denim, with successful results. It states on the American Association of Textile Chemists and Colorists (AATCC)’s fashion blog that independent lab tests show brrr° denim feels 38% cooler to the touch than comparable traditional denim, dries up to 47% faster and wicks 2.5 times better. And aside from this, brrr° has taken steps in the energy harvesting field, having received a patent using piezoelectrics technology. “Somewhere down the road you may be able to stick a device in your back pocket and charge it from your clothing,” says Credeur, who adds that the company hasn’t actioned the patent just yet but considers it a “cool technology to explore.” Micro minerals of any kind are bound to raise questions over their safety to human health and the environment, but Credeur assures that the minerals used by brrr° are safe. “Our proprietary mineral blend is not reactive and absorbed by skin at all,” she says. “It’s an organic material but it’s combined with a man-made one, blending into this master batch as it gets produced. Its behaviour is no different to any other polyester or nylon or base material.”

The technology has also found itself being used in recycled fabrics. “We do have GRS [Global Recycle Standard] certified suppliers of recycled yarns,” says Credeur. “We buy yarn that has recycled material in it and integrate brrr° technology into it as part of the manufacturing process. There’s a lot of talk and interest in recycled material and, with some brands that are very forward thinking, they tend to be hungrier for that technology. They’re also willing to pay more as it’s a premium product.” Credeur reveals that brrr° is planning to enhance the technology to increase the surface area of the minerals effectively and amplify the cooling effects. “We’re exploring some new dispersion technologies, how we blend the minerals, and how we integrate the minerals with the actual yarn in the first place,” she says. “If you can increase the surface area, you can directly improve the effect of the cooling minerals.” She adds: “Down the road there will be additional hiring and additional fundraising to grow.” This is particularly important as there are educational hurdles to overcome with brrr° technology to explain to retailers and consumers how and why it’s better than previous generation technologies that claimed to be cooling but were ‘really just wicking.’ “The challenge is being able to capture the attention and articulate the benefits quickly in a way that people can understand how it’s different and why it’s different, and how the science works,” says Credeur. “It’s about getting our name out there,” she adds. “People want clothing that does something more for them – they want comfort, they want it to wick and to dry quickly. We see ourselves as part of the solution – the planet is not getting any cooler.”

Original Article: Wtin

Women’s Beauty And Fashion For A Summer Vacation 2020 Features brrrº

Recent developments happening in the world has lead most Americans to vacation at home during these uncertain times. As history would have it, at the turn into the 20th century city-dwellers would vacate their city homes for beach and lake houses. At that time, the USA coined the term vacation.

I am well-aware that many other nations follow the English and prefer to employ the term holiday, nevertheless, the USA prides itself in being delightfully creative - perhaps why we still use vacation to this very day.

The nature of vacation has changed in summer 2020. For example, in the past, a vacation meant that we were absent from the workplace. Whereas today, while on vacation, it is considered normal to remain on-call in lieu of being unreachable.

In a word, technology has changed the impact on human life. Rapid transmission in communications is at the forefront of almost everything we do. I for one am always telecommunicating and remaining plugged-in whilst on vacation. It is part of our lifestyles now. Case closed? Not yet.

This summer, be mindful that your wardrobe is required to appear up-to-date more than ever! Why? Instagram, that’s why. These days, many people are posting images and video of us and them.

Henceforth, I am presenting to you here a bevy of fashion and beauty products from beauty, to bags to swimsuits, to footwear... in order for you to take the leading role (prior to planning your vacation) during chic social engagements and fun in the sun.

Enjoy your vacation America. Lord knows we all need it this summer!

A sleeveless long crop tailored to fit in all the right places, ADAY’s Cool Down Crop is actually three tops in one. Designed to be worn open, closed, or wrapped with the snap function, you’ll still be finding new ways to wear it long after summer has ended. Made from ADAY's Cool Weave fabric (powered by brrr° technology), it will literally cool you down as your day heats up. The patented Triple Chill Effect uses cooling minerals to provide an immediate + continuous cooling effect; active wicking to move moisture away for nonstop comfort; and rapid drying to deliver a fresh + crisp experience. It’s machine washable, offers UV protection for UPF 50+, and comes in two chic colors: coconut and forest.

Original Article found here

brrr° Featured at the Functional Fabric Fair

This year’s digital New York Functional Fabric Fair focused on nature-inspired advances in fabric, and brrr° is honored to have been included in the exhibits for cutting-edge fabrics.

The central theme of the show was finding ways to care for our environment by incorporating natural fibers or waste, recycled fibers or waste, environmentally-friendly production methods, and biodegradable or recyclable materials into fabric manufacturing.

The organizers of the Functional Fabric Fair Powered By Performance Days posed an important question to attendees: How can performance fabrics be both natural and functional?

By tapping into the natural properties of materials produced by nature — such as thermoregulation, moisture management and UV protection — fabric manufacturers can make significant advances in performance in an ecologically sustainable and responsible way.

brrr° prioritizes keeping its carbon footprint as small as possible, and offers recycled options for hundreds of fabrics in its library.

The brrr° cooling fabrics were featured at the Functional Fabric Fair include:

- Close to skin and base layer

- brrr° K0146 (cooling stretch polyester) — Made with 82% brrr° Polyester, 18% Elastane/Spandex

- Pants woven

- brrr° D0003 (cooling stretch denim) — Made with 68% Cotton, 9% brrr° Polyester, 6% brrr° Nylon, 15% brrr° Rayon, 2% Elastane/Spandex

- Shirts woven

- brrr° W0041-1R (cooling stretch twill weave) — Made with 48% brrr° Nylon, 44% Recycled brrr° Nylon, 8% Elastane/Spandex

Thank you to our colleagues across the textile industry for sharing your knowledge and latest product developments at the Functional Fabric Fair. We always learn a great deal from this talented group, and it’s inspiring to see how innovative companies are looking to Mother Nature to improve their performance fabrics.

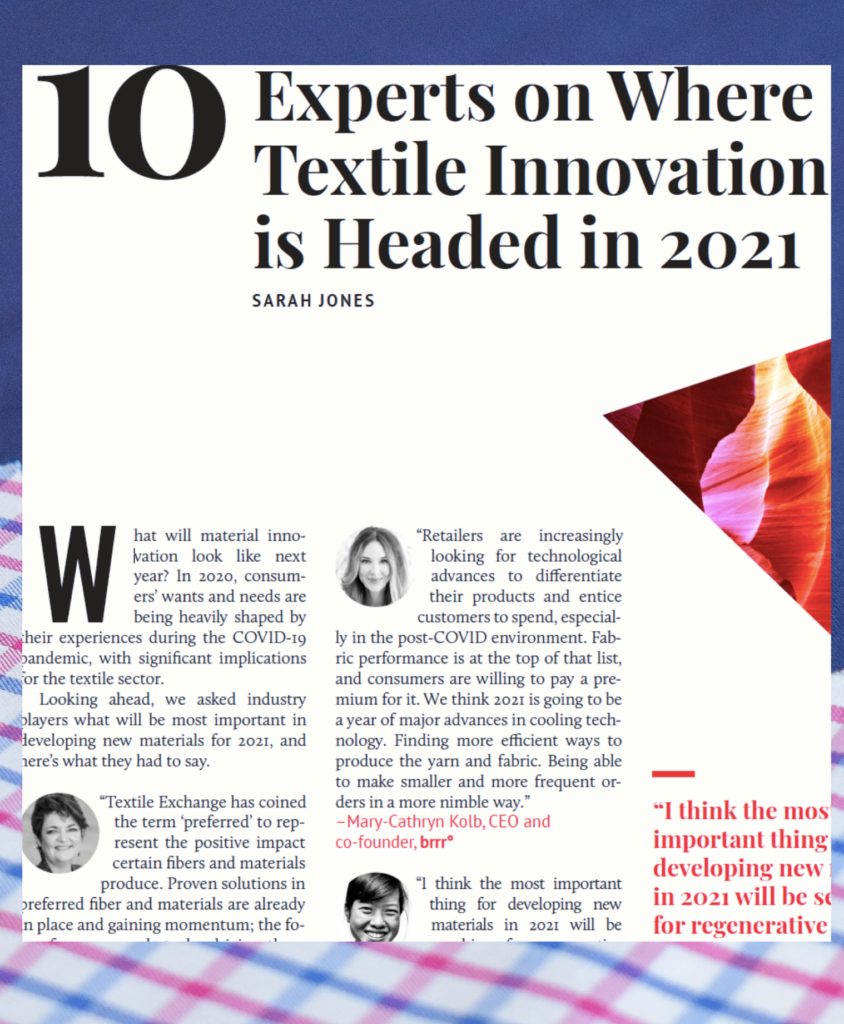

Sourcing Journal Features Mary-Cathryn Kolb

Thank you to Sourcing Journal reporter Sarah Jones for featuring brrr° Founder & CEO Mary-Cathryn Kolb in their Material Innovation 2020 report, which explores emerging trends in the textile industry!

Jones asked several executives from companies including The North Face, DuPont, Schoeller, Lenzing Group and brrr° to share their thoughts on what fabric innovation will look like in 2021 — especially in light of changing consumer needs and wants since the COVID-19 pandemic.

Jones asked several executives from companies including The North Face, DuPont, Schoeller, Lenzing Group and brrr° to share their thoughts on what fabric innovation will look like in 2021 — especially in light of changing consumer needs and wants since the COVID-19 pandemic.

The responses were far-ranging and diverse, which was very refreshing and encouraging to see.

Textile executives touched on things as varied as the role e-textiles could play in capturing vital statistics like pulse rate and oxygen levels; advances in sustainability and traceability throughout the supply chain; and demonstrating the benefits of advanced fabrics through testing and scientific study.

Kolb said one major development she expects to see in 2021 is more demand from retailers and consumers for advanced products that do something to help people feel more comfortable. She also expects to find greater efficiencies in production and supply chains to give retailers more flexibility on order sizes as they test new products.

“Retailers are increasingly looking for technological advances to differentiate their products and entice customers to spend, especially in the post-COVID environment,” Kolb said.

“Fabric performance is at the top of that list, and consumers are willing to pay a premium for it. We think 2021 is going to be a year of major advances in cooling technology. Finding more efficient ways to produce the yarn and fabric. Being able to make smaller and more frequent orders in a more nimble way.”

Subscribers to Sourcing Journal can download the full report here.

Sustainability and Value Article featuring brrrº

The textile industry turns to biomaterials and biomimetics for green alternatives.

by Glenna B. Musante

As the textile and outdoor gear communities look for ways to limit the use of petroleum products, apparel and gear brands, as well as ingredient manufacturers within the textile industry supply chain, are beginning to replace or augment plastics and polyester with biomaterials. Textile companies are also turning to biomimetic processes.

Jan Beringer, senior scientific expert with the Hohenstein Institute for Textile Innovation, said this growing trend in the textile industry is tied largely to sustainability. But that is not the only reason textile companies are turning to Mother Nature for materials and design inspiration. Some natural products and processes can enhance the performance value of a product.

Natural successes

Beringer, who was interviewed at the 2020 Winter Outdoor Retailer and Snow Show in Denver Colo., said companies across the textile sector are finding new ways to improve the degradation of synthetic textiles in the environment without sacrificing performance.

“The textile industry needs to make a greener product,” he said, while at the same time maintaining the performance characteristics consumers expect. “This has been a constant effort for the last one to five years.”

He named DuPont Sorona® as an example. DuPont describes Sorona in marketing materials as a textile “on the forefront of the shift from oil-based materials to bio-based ones.” Developed by the R&D labs at DuPont, Sorona is made, in part, with glucose. The manufacturing process involved begins with harvesting crops, then extracting glucose from those crops and adding microorganisms to the glucose to begin a fermentation process (similar to the production of alcohol). Fermentation replaces chemical synthesis, producing PDO (1,3-Propanediol). TPA (terephthalic acid) is added to the Bio-PDO, creating a molecular bond.

DuPont describes Sorona as a high-performance polymer with a variety of end-product applications. Sorona Revive Fabric, for example, can be used in applications with Spandex to add stretch in addition to recovery for apparel shape-retention. DuPont adds that 37 percent of the end polymer is made from annually renewable plant-based ingredients.

According to Beringer, a number of natural materials are being used by the textile industry to develop bio-based fabrics or fabric blends, including milk, corn starch, and algae (which uses CO2 from the atmosphere).

Enhanced performance

Formed in 2014, brrr° is a relatively new fabric technology that incorporates salts and natural minerals into the extrusion mix for a synthetic textile that has cooling properties. Mary Jane Credeur, speaking on behalf of brrr°, described this as a cooling technology integrated into a polyester or nylon blend. “The secret sauce,” she said, “is a master bend of salts and cooling minerals,” developed in 2014 by a team led by Mary-Cathryn Kolb, the former director of sales for SPANX®.

Basically, the salts and minerals are pulverized and then added to the polymer. The technology is a component of several high-end products including golf apparel from Greyson and women’s dresses from Southern Tide.

Breaking down degradation

Other companies are adding biomaterials to synthetics, such as polyester, to facilitate a process similar to biodegradation. That, however, is what Dr. Sonja Salmon, associate professor of textile engineering at NC State’s Wilson College of Textiles described as a “complicated space,” due to potential misunderstandings related to the various stages of a textile’s decomposition.

The first step, Salmon said, is deconstruction. This is where a textile product is taken apart. The next step is disintegration, which is where a textile is physically broken apart into smaller microscopic fragments. The last is degradation, which refers to a chemical conversion of a larger or more complex chemical structure into simpler chemical structures. A sub-group of degradation, she added, is biodegradation, where the remaining particles go through a chemical conversion into energy that can be consumed.

“When you eat something, you are biodegrading it,” she said, “and those layers are very important when we start talking about polyester or other acrylics.”

California state law, for example, has strict rules related to the use of the word “biodegradation” in connection with any polyester product. California law SB 567 prohibits any plastic product sold within the state to be labeled as “biodegradable,” “degradable,” or “decomposable,” or any form of those terms.

Sustainable synthetics

The makers of CiCLO® additive technology, a new fiber option in the textile industry supply chain, have taken that guideline to heart as they bring a new, more sustainable synthetic fiber technology to market. CiCLO chemistry is added to polymers during the extrusion process, which helps fabrics, such as polyester, break down in a way that’s similar to wool at the end of a product’s life cycle. According to materials from Parkdale Mills, which is marketing the new fiber to the textile industry, the additive technology accelerates the speed at which a synthetic fiber biodegrades in the ocean or a landfill.

CiCLO is a product of California-based Intrinsic Textiles Group LLC, which was formed to develop and commercialize sustainable, closed loop solutions for textiles. According to Cheryl Smyre, brand manager and director of advanced materials at Parkdale, apparel manufacturers can easily integrate the technology into their supply chain.

She adds that brands in the performance sector are looking for ways to manufacture apparel made from synthetic fibers less polluting, without losing the performance strengths of synthetics such as polyester and nylon.

“Extensive testing by reliable third-party laboratories over a number of years has proven that CiCLO technology is effective at reducing synthetic fiber accumulation in landfills and microfiber pollution in the oceans,” Smyre said. “At the same time, products made from CiCLO additive polyester can be washed and cared for just as you would any other polyester apparel item.”

She adds that CiCLO fibers and yarns can play a role in reducing the impact of textile waste in landfills and synthetic microfibers in the oceans generated by the high volumes of Personal Protective Equipment (PPE) that will be used as the world fights the COVID-19 pandemic.

Plant-based performance

Other companies in the outdoor apparel and gear sector that are using biomaterials to replace or supplement synthetics include NEMO Equipment and Reima USA Heiberg/Beringer. NEMO is a camping gear brand that sells sleeping bags and tents, among other products.

Currently NEMO is looking at milkweed as a biomimetic model for plant-based insulation. Milkweed is an American wildflower that produces a fluffy material that has many of the same properties as down. The fluff attached to milkweed seeds is buoyant and very warm. In the past it’s been used to stuff mattresses and pillows, as well as line winter clothing and footwear. It was also used during WWII as the stuffing for life jackets.

Reima USA Heiberg/Beringer has introduced a winter jacket made from what they describe as a “heat-storing coffee bean shimmer fabric.” Reima is a leading premium performance wear brand for children. At Winter Outdoor Retailer they showcased a jacket made in part with ground coffee beans. Carbonized coffee bean particles are mixed in the polymer with polyester and add what Reima says is rapid heat storage and “a gorgeous sheen.”

Other companies that serve the outdoor industry are also looking for ways to replace plastics with biomaterials. Costa Sunglasses, based in Dayton Beach, Fla., manufactures a line of high-end sunglasses with frames made from bio-resins derived from castor bean oil, which has a smaller overall carbon footprint than plastic. The company says the frames are designed to be durable, lightweight, and hold shape under harsh conditions.

All of these developments, which are taking place in textile labs around the globe, reflect a trend on the rise, said Beringer. Most are driven by a desire to improve the sustainability quotient of the apparel and gear that brands are selling to the world. And those efforts are needed now more than ever.

Glenna B. Musante is a freelance writer who specializes in the textile industry.

Find the article here: Advanced Textile Source

Amplifying the Cooling Effects of brrr°

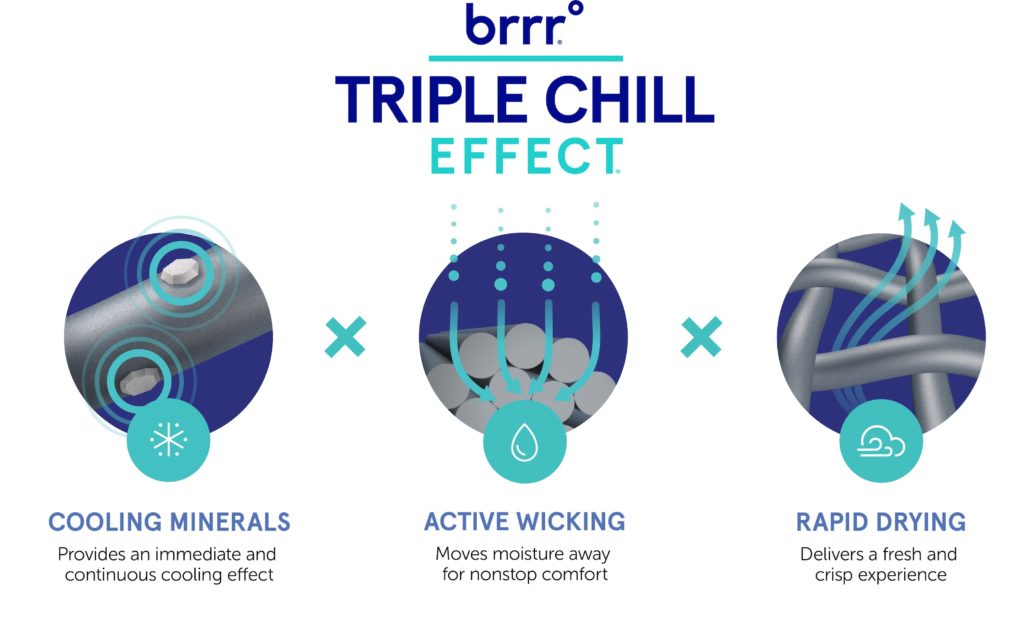

brrr comprises the Triple Chill Effect to cool, wick and dry

Busy, active lifestyles coupled with the ongoing climate crisis that continues to dominate the headlines, is driving the demand for innovative cooling solutions in all aspects of our daily lives. And, as textiles are omnipresent, they naturally make a great vehicle for administering such solutions.

Feeling cool and comfortable in whatever activity we’re doing heightens our overall wellbeing and performance. So, with this in mind, the company brrr° set out to explore how textiles can be enhanced to meet this need.

Founded in 2014 by Mary-Cathryn Kolb, a retail industry expert who has worked for apparel brands such as Spanx and Von Dutch, brrr° developed a proprietary cooling fabric technology that can be integrated into any existing fabric to bring immediate and continuous cooling. To do so, a secret blend of natural minerals are embedded into the yarn itself to become a permanent part of the fabric that, unlike coatings or sprays, doesn’t wash out over time.

Explaining the process in more detail, Mary Jane Credeur, a spokesperson for brrr°, says: “We begin by adding our secret blend of minerals into the nylon or polyester pellets, which are extruded as yarn that is then turned into fabric. Our cooling minerals are permanent and part of the structure of the yarn. Under a microscope you can actually see the little mineral speckles.”

The cooling feature is combined with wicking and rapid drying technology to form what brrr° calls the Triple Chill Effect. For instance, brrr° nylon and brrr° polyester are described as ‘cool to the touch’ with more chill than comparable competitors, while the wicking technology moves moisture away from the skin, for ‘non-stop comfort’, and the quick drying capability rapidly releases moisture into the air, cooling the fabric and providing a ‘fresh and crisp’ experience.

To realise the potential of the technology, brrr° has several ‘go-to’ mill partners in Taiwan who are considered a part of its R&D team. All brrr° products are tested by independent labs to prove the effectiveness. For instance, tests conducted last year by Intertek Testing Services found that brrr° nylon and polyester fabrics consistently outperformed numerous other comparable products in lab tests that measure Qmax (cool to the touch feeling), wicking and dry time.

“For years, a lot of the apparel manufacturers claimed that their products were cooling but they were just wicking, they didn’t actually draw away heat per se. Some products you have to get wet before they cool, and that’s not very practical. The science behind it, that’s our pedigree. It’s not just a gimmick that’s going to wear out over time like sprays or coatings do,” says Credeur.

END USES

An obvious application for the technology would be activewear and outdoor wear, where users are prone to working up a sweat, but Credeur says the end uses span various elements of a consumer’s wardrobe and lifestyle. And, as an ingredient brand, brrr° has garnered interest from various retailers and manufacturers looking to integrate the cooling fabric technology into their collections.

Credeur says: “A lot of our launches have been casual polo shirts, so not just outdoor wear, but also casual weekend wear, office wear, dress shirts, linings of suits, and undergarments – we’re in talks with a few co-branded partners. Plus, we have a new line launching with CAT Workwear from Caterpillar – an outdoor, rugged apparel line.”

Home textiles are another key end use, particularly bed sheets. “There tends to be more demand around things you actually touch and interact with,” says Credeur. “Sheets are an obvious one, as memory foam mattresses make you sweat a little bit more. Women who are menopausal or pre-menopausal tend to appreciate that a lot. We think that someday we’ll get some demand from sofa material coverings and fabric for upholstery. And we have been in talks with auto manufacturers for car seat materials.”

The company has also integrated its cooling fabric technology into denim, with successful results. It states on AATCC’s fashion blog that independent lab tests show that brrr° denim feels 38% cooler to the touch than comparable traditional denim, dries up to 47% faster and wicks 2.5 times better.

And aside from this, brrr° has taken steps in the energy harvesting field, having received a patent using piezoelectrics technology. “Somewhere down the road you may be able to stick a device in your back pocket and charge it from your clothing,” says Credeur, who adds that the company hasn’t actioned the patent just yet but considers it a ‘cool technology to explore’.

ENVIRONMENTAL EDGE

Micro minerals of any kind are bound to raise questions over their safety to human health and the environment, but Credeur assures that the minerals used by brrr° are safe. “Our proprietary mineral blend is not reactive and absorbed by skin at all,” says Credeur. “It’s an organic material but it’s combined with a man-made one, blending into this master batch as it gets produced. Its behaviour is no different to any other polyester or nylon or base material.”

The technology has also found itself being used in recycled fabrics, as the textile industry continues to boost its sustainability profile. “We do have GRS [Global Recycle Standard] certified suppliers of recycled yarns,” says Credeur. “We buy yarn that has recycled material in it and integrate brrr° technology into it as part of the manufacturing process. There’s a lot of talk and interest in recycled material and, with some brands that are very forward thinking, they tend to be hungrier for that technology. They’re also willing to pay more as it’s a premium product. Some brands are not quite there yet, and you have to respect that as well. It’s what the customer wants and what the market wants, especially the younger generations who tend to be curious about where their products come from.”

NEXT STEPS

Credeur reveals that brrr° is planning to enhance the technology to increase the surface area of the minerals effectively and amplify the cooling effects. “We’re exploring some new dispersion technologies, how we blend the minerals, and how we integrate the minerals with the actual yarn in the first place,” she says. “If you can increase the surface area, you can directly improve the effect of the cooling minerals.”

New products based on this technology will be rolled out this year, in line with the company’s fifth anniversary. “We’re really starting to get traction with a couple of national and international retailers,” says Credeur. “Down the road there will be additional hiring and additional fundraising to grow.”

This is particularly important as Credeur says there are educational hurdles to overcome with brrr° technology to explain to retailers and consumers how and why it’s better than previous generation technologies that claimed to be cooling but were ‘really just wicking’.

“The challenge is being able to capture the attention and articulate the benefits quickly in a way that people can understand how it’s different and why it’s different, and how the science works,” she says.

Credeur adds: “It’s about getting our name out there. People want clothing that does something more for them – they want comfort, they want it to wick and to dry quickly. We see ourselves as part of the solution – the planet is not getting any cooler.”

To find out more about brrr° Triple Chill Effect technology, visit https://brrr.com/

Have your say. Tweet and follow us @WTiNcomment

Source: WTIN

CNBC Upstart 100 Recognizes brrr° as an Innovative Leader

By Mary-Cathryn Kolb, Founder & CEO of brrr°

Each year, a panel of editors and business leaders at CNBC select 100 of the most influential startup companies in the nation.

The judges consider whether these young companies are shaking up established industries or finding creative ways to solve vexing problems, and hundreds of companies apply each year.

Past winners of the CNBC Upstart 100 ranking include women’s intimate apparel company ThirdLove, electric toothbrush maker quip and ATTN:, a digital entertainment news platform backed by Ryan Seacrest.

This year, we are incredibly humbled and honored that brrr° was chosen for the CNBC Upstart 100.

I started brrr° with a vision to improve the fabrics we wear and touch in our everyday lives with advanced cooling, wicking and drying technologies. We are restless and relentless as we invest heavily in research and development to hunt for new ways to make cooling fabric even better.

And we are certain that consumers are hungry for more. The textile industry is making major strides in cooling fabric technology innovations, and that segment of the fabric industry has a projected compound annual growth rate of more than 11% through 2025.

A Leap Forward for Cooling Fabric

Several decades ago, the apparel industry started to improve fabric by adding features like spandex for stretch and incorporating wicking technology into the yarn.

The wicking feature drew away moisture, which promoted the evaporation of sweat. Some retailers equated wicking with cooling and started to call their clothing “cool” — even though it didn’t actually draw away heat or feel cool to the touch.

But it sounded good in advertisements for things like cooling shirts and consumers seemed to like it, so the industry became complacent and “moisture wicking” was widely adopted by companies that make athletic apparel, casual clothes, and even some business and office wear.

Things pretty much stalled after that.

Most fabrics didn’t get a whole lot of attention or innovation until a handful of years ago when consumers began to demand more from their clothing, bedding, furniture coverings and other fabrics.

It was high time for fabric to take a major leap forward in performance and comfort.

Could performance fabric actually improve our focus, concentration, and confidence at work and at play?

Could advanced textiles draw heat and moisture away from our skin?

Could fabric actually keep us cooler?

Why, yes. Yes, it can.

The Struggle for Thermoregulation is Real

Our bodies work hard to regulate our temperature and keep it as close to 98.6 degrees Fahrenheit as possible.

When we are too cold, our muscles shiver to create warmth. When we are too hot, we sweat and the evaporation of that sweat draws away heat to cool us off.

This struggle for thermoregulation is constant, and when we’re on the wrong end of it, we can quickly become exhausted and lose focus.

Our clothes often exacerbate the situation, trapping heat and moisture. That can make us feel self-conscious, distracted and lethargic — and hinders our performance.

In a survey by CareerBuilder, nearly a quarter of workers in the U.S. said a workplace that’s too hot makes it difficult to concentrate and negatively impacts their productivity.

For athletes, fatigue and distraction can hurt performance just as much as actual muscle pain and physical exhaustion, according to Sports Illustrated.

An increasingly hot planet isn’t helping. Earth has been rapidly warming for several decades, and July was the hottest month on record.

Cooling fabric technology can help our bodies do a better job at thermoregulation.

By drawing heat and moisture away from our skin, fabric that stays cool in the heat can help keep our core temperature closer to the ideal 98.6 degrees Fahrenheit.

Natural Cooling Minerals

Earlier in my career, when I was an executive at SPANX, I became intrigued by the tiny little fibers that could stretch, lift and support our bodies so effectively.

I began to wonder: what if those little fibers could do even more for us? What if they could actually help keep us cooler and more comfortable?

I left the corporate world in late 2014 to start learning everything I could about cooling fabric technology, and soon the idea for brrr° took shape.

Scientists and researchers have known for years that certain natural minerals can create a cooling sensation. These blends of salts and other minerals are very efficient at conducting heat, which enhances the natural thermoregulation that our bodies are constantly doing.

We developed and tested numerous recipes for cooling minerals before landing on the ideal combination — a proprietary blend of brrr° cooling minerals that work together to instantly and continuously draw heat away from the skin.

Those secret mineral blends are embedded right into nylon or polyester yarns that are later made into fabric, which means the brrr° cooling minerals are a permanent part of the structure of the textile and won’t ever fade or wash out over time. That’s a big difference compared with some other companies that achieve a cooling sensation with sprays and coatings, which are temporary and eventually diminish after repeated washings.

brrr° cooling minerals are a major innovation in cooling fabric technology, and independent lab testing proves it.

One way to test whether fabrics are “cool to the touch” is with Qmax testing, which is an internationally recognized and respected test used by the textile industry.

brrr° cooling nylon is more than twice as cool as other brands in Qmax testing, while brrr° cooling polyester also handily outperforms competitors.

The Triple Chill Effect

brrr° cooling minerals are just one leg of the stool for creating the most cooling fabric.

When our proprietary blend of cooling minerals is combined with other innovations such as active wicking and drying technologies, these three cooling elements work together and amplify each other’s cooling capabilities in a more powerful way.

Together, brrr°’s natural cooling minerals, active wicking, and rapid drying technologies create a “Triple Chill Effect” that consistently outperforms other brands in independent tests by globally recognized labs.

For example, in a standard test used by the fabric industry, brrr° nylon wicks 30 minutes faster than some other products, and the dry rate for brrr° nylon and polyester fabrics is several minutes faster than some other brands.

You can see the full results of independent lab tests on brrr° fabrics here, and here’s a short video that shows how the brrr° Triple Chill Effect makes fabrics cool.

brrr° licenses its cooling fabric technology to other retailers and manufacturers as a premium ingredient brand, and it has quickly been adopted by Jos. A Bank and Men’s Wearhouse to make cooling shirts for the office. Southern Tide uses brrr° to make cooling shirts, cooling shorts and other casual apparel. Mizzen+Main, Greyson golf apparel, NinetyEight6 tennis apparel, Coral Coast Clothing, and CAT Workwear also make their clothing even better with brrr°.

Business Insider Says It’s ‘Perfect’

The cooling capabilities of brrr° have also been winning accolades from major business media publications.

Business Insider recently tested the Southern Tide Intercoastal Performance Sport Shirt featuring brrr° alongside eight other cooling shirts and raved about the comfort and crispness of brrr°.

“I tested this shirt on one of the first warm days of the year, and beyond reducing sweat, the fabric really helped keep me cool throughout the day,” wrote Danny Bakst of Insider Picks for Business Insider. “The shirt is exceptionally stretchy, and is perfect for the transition from the office to happy hour.”

Forbes writer Jeff Kart recognized our scientific rigor in a recent article, saying: “Test data from an independent lab that shows brrr°’s technology can keep people cooler and more comfortable in everyday activities.”

Delta Sky Magazine lauded the way things made with brrr° are “specially designed to beat the heat.”

Where We Go From Here

But we’re not resting on our laurels. brrr°’s pursuit of new advances in cooling fabric technology is just as unrelenting as it was on our first day in business.

We invest heavily in research and development, and at any given time we have dozens of new products or techniques going through rigorous testing to determine whether they deserve a spot in our library of 500 fabrics and products.

Some of the things we are excited about include advanced methods for cooling mineral dispersion, and the potential for amplifying the effects of certain materials by increasing the surface area of the minerals in the yarn.

Those are just a couple ways brrr° is working hard to shake up the textile industry with better cooling fabric technology, as the judges of the CNBC Upstart 100 ranking recognized.

Whatever the future of cooling fabric technology brings, brrr° will be front and center as a tireless and relentless innovator.

brrr° Founder & CEO Mary-Cathryn Kolb Selected for EY Entrepreneurial Winning Women™ Class of 2019

ATLANTA — November 6, 2019 – EY announced today that Mary-Cathryn Kolb, Founder and CEO of cooling fabric innovator brrr°, was chosen as one of the 13 women founders selected for the EY Entrepreneurial Winning Women™ North America Class of 2019. The program, which is in its 12th year, identifies ambitious women entrepreneurs who are leading thriving organizations and provides the access, advisors and resources needed to scale their companies to their full potential and ultimately become leading market innovators. Program engagement offers participants executive education and introductions to the vast EY global entrepreneurial ecosystem as well as the Entrepreneurial Winning Women community worldwide.

“This opportunity to develop stronger leadership and operational skills alongside this incredibly talented group of women is an impactful experience that will make brrr° more effective and competitive,” Kolb said. “Implementing the insights, ideas and tools shared among this network of visionary entrepreneurs will help brrr° become more strategic, nimble and resourceful. I am so grateful to be part of this program, and part of the global EY family.”

This year’s class of women-led high-growth companies across the US and Canada span a variety of industries, with a particularly strong showing in the technology sector, including three innovating in FinTech. More than one-third of the companies are tech-focused, with offerings ranging from innovative and money-saving payment solutions for SMEs to patented textile technology designed to cool the wearer in minutes. Additional sectors include diverse and inclusive beauty products, clean energy financing, nutrition-driven food production and innovative health and wellness products. The judging panel for the Class of 2019 consisted of Beth Ferreira, General Partner of FirstMark Capital; David Liu, Co-founder of XO Group, Inc. (formerly The Knot, Inc.); Nicole Smith, Founder and CEO of Flytographer; and Naomi Whittel, Founder & CEO of Naomi Whittel Brands.

“Acceptance into the Entrepreneurial Winning Women program is a testament to these founders’ drive, grit and vision,” said Lisa Schiffman, EY Entrepreneurial Winning Women Global Program Lead and a Director with Ernst & Young LLP. “EY is delighted to once again have the opportunity to offer critical resources, guidance and community so these women founders can more readily scale their businesses beyond what they may have initially thought possible.”

The North America program targets women business owners who are founding CEOs of any US or Canadian privately held company less than 10 years old. Company revenues typically range from at least $2 million to as much as $30 million annually.

This year’s class convened for the first time at a two-day orientation in New York City this September. The entrepreneurs took part in educational sessions including pitch coaching, TRACOM Social Styles® and building a public profile. On an ongoing basis, Entrepreneurial Winning Women take part in additional workshops, conferences and training sessions; become part of the EY global community of more than 500 Entrepreneurial Winning Women on every continent; and forge connections to a vast community of EY Entrepreneur Of The Year™ alumni throughout the world.

“As advisors to the ambitious, we feel privileged to be a part of these founders’ business journeys,” said Lee Henderson, EY Americas Growth Markets Leader. “The program underscores EY’s continued commitment to foster the success of women entrepreneurs and reinforce their positive impact on the global economy.”

The Class of 2019 will be officially recognized during the Strategic Growth Forum® US November 13-17, 2019, in Palm Springs, California. Founded and produced by EY, the Forum is the country’s most prestigious gathering of high-growth, market-leading companies, bringing together more than 2,000 of the nation’s top executives, entrepreneurs, advisors, investors and other business leaders.

About brrr°

brrr° was founded in 2014 to develop technologically advanced fabrics with superior cooling performance to promote comfort in the items we touch in our everyday lives. brrr° enhances the cooling capabilities of business clothing, casual clothing, athletic apparel, denim, uniforms, sheets and many other textiles. The privately held Atlanta-based company is led by Founder and CEO Mary-Cathryn Kolb, who previously held senior positions at Spanx, Seven Jeans, TOMS Shoes and Von Dutch. For more information, please visit www.brrr.com.

Media contact for brrr°:

Mary Jane Credeur | The Credeur Group

mj@credeurgroup.com | 404.317.2718

About EY

EY is a global leader in assurance, tax, transaction and advisory services. The insights and quality services we deliver help build trust and confidence in the capital markets and in economies the world over. We develop outstanding leaders who team to deliver on our promises to all of our stakeholders. In so doing, we play a critical role in building a better working world for our people, for our clients and for our communities.

EY refers to the global organization, and may refer to one or more, of the member firms of Ernst & Young Global Limited, each of which is a separate legal entity. Ernst & Young Global Limited, a UK company limited by guarantee, does not provide services to clients. Information about how EY collects and uses personal data and a description of the rights individuals have under data protection legislation is available via ey.com/privacy. For more information about our organization, please visit ey.com.

This news release has been issued by EYGM Limited, a member of the global EY organization that also does not provide any services to clients.

About EY Growth Markets

EY Growth Markets professionals connected across the globe are trusted business advisors to CEOs, owners and entrepreneurs leading private and family enterprises, including those managing increasing flows of private capital worldwide. We have a long legacy advising these ambitious leaders in realizing their ambitions, faster. With private entities making up more than 90% of EY clients, our professionals appreciate the owner mindset and possess the know-how needed to think differently about delivering business results, practically and sustainably. ey.com/private

IFAI Women in Textiles Summit Announces Program

The event will take place from 19-21 February 2020 in Nashville, TN. © IFAI

After a successful inaugural event, the IFAI Women in Textiles Summit will once again join experienced and emerging leaders to discuss current challenges, diverse perspectives, and creative approaches.

The event organized by the Industrial Fabrics Association International (IFAI), will take place from 19-21 February 2020 in Nashville, TN, expecting current and future leaders from industry segments including advanced textiles, geosynthetics, marine, military, specialty fabrics, and shade and weather.

After the welcome reception on 19 February, the event will feature a range of panel discussions over the following two days. “The goal of the summit is to strengthen the advancement of women and men through an interactive forum that provides education, networking, and dialogue about important issues affecting women in business. The event will explore how women are contributing to the success of their organizations and the textile industry,” organizers report.

The first day of the summit will start off with a casual and energizing networking session, which will provide time to chat about trending topics and share your triumphs and challenges. It will be followed by an opening keynote presentation entitled Lab Coats & Lipstick: Staying Close to R&D, Harnessing Your Network and Mentoring Future Leaders. Mary-Cathryn Kolb, founder, and CEO of brrr° will talk about how her early career prepared her for becoming an entrepreneur, and the importance of staying closely involved in R&D. She will discuss how invaluable her professional network has been in opening doors with potential customers and investors.

Communicating in a firm, yet approachable manner can be difficult for many women. Stop Saying 'Please' by Rachal McCarthy, President of NTI Global, will discuss several key phrases and methods of expression which can be used to diffuse a situation, set a new tone, and provide clear boundaries.

Samantha Marion, Textile Development Manager for Top Value Fabrics & Laura Martin, Purchasing Manager for Top Value Fabrics, will lead an interactive discussion about the imposter syndrome, exploring tools to combat this albatross that can weigh down the success of talented women.

Stephanie Rodgers, Director Advanced Product Development, Apex Mills, will highlight a few women from different backgrounds that have used textiles as a platform for science and innovation, highlighting e-textiles and how attendees can encourage this new market sector.

After a series of roundtable discussions, Power, Presence and Impact for Women by Karen Hinds, author, and founder and CEO of Workplace Success Group, will use data and proven strategies to demonstrate how women can own their power and develop their competitive edge.

On 21 February, the morning yoga session will start the second morning off with self-care that helps you reflect on the prior day's education while connecting with colleagues.

Finally, the panel discussion on The Next Generation: Attract, Mentor and Develop Future Leaders will help understand both sides of the talent development process and shed light on mentoring the next generation of leaders.

Article is from Innovation in Textiles