Sustainability and Value Article featuring brrrº

The textile industry turns to biomaterials and biomimetics for green alternatives.

by Glenna B. Musante

As the textile and outdoor gear communities look for ways to limit the use of petroleum products, apparel and gear brands, as well as ingredient manufacturers within the textile industry supply chain, are beginning to replace or augment plastics and polyester with biomaterials. Textile companies are also turning to biomimetic processes.

Jan Beringer, senior scientific expert with the Hohenstein Institute for Textile Innovation, said this growing trend in the textile industry is tied largely to sustainability. But that is not the only reason textile companies are turning to Mother Nature for materials and design inspiration. Some natural products and processes can enhance the performance value of a product.

Natural successes

Beringer, who was interviewed at the 2020 Winter Outdoor Retailer and Snow Show in Denver Colo., said companies across the textile sector are finding new ways to improve the degradation of synthetic textiles in the environment without sacrificing performance.

“The textile industry needs to make a greener product,” he said, while at the same time maintaining the performance characteristics consumers expect. “This has been a constant effort for the last one to five years.”

He named DuPont Sorona® as an example. DuPont describes Sorona in marketing materials as a textile “on the forefront of the shift from oil-based materials to bio-based ones.” Developed by the R&D labs at DuPont, Sorona is made, in part, with glucose. The manufacturing process involved begins with harvesting crops, then extracting glucose from those crops and adding microorganisms to the glucose to begin a fermentation process (similar to the production of alcohol). Fermentation replaces chemical synthesis, producing PDO (1,3-Propanediol). TPA (terephthalic acid) is added to the Bio-PDO, creating a molecular bond.

DuPont describes Sorona as a high-performance polymer with a variety of end-product applications. Sorona Revive Fabric, for example, can be used in applications with Spandex to add stretch in addition to recovery for apparel shape-retention. DuPont adds that 37 percent of the end polymer is made from annually renewable plant-based ingredients.

According to Beringer, a number of natural materials are being used by the textile industry to develop bio-based fabrics or fabric blends, including milk, corn starch, and algae (which uses CO2 from the atmosphere).

Enhanced performance

Formed in 2014, brrr° is a relatively new fabric technology that incorporates salts and natural minerals into the extrusion mix for a synthetic textile that has cooling properties. Mary Jane Credeur, speaking on behalf of brrr°, described this as a cooling technology integrated into a polyester or nylon blend. “The secret sauce,” she said, “is a master bend of salts and cooling minerals,” developed in 2014 by a team led by Mary-Cathryn Kolb, the former director of sales for SPANX®.

Basically, the salts and minerals are pulverized and then added to the polymer. The technology is a component of several high-end products including golf apparel from Greyson and women’s dresses from Southern Tide.

Breaking down degradation

Other companies are adding biomaterials to synthetics, such as polyester, to facilitate a process similar to biodegradation. That, however, is what Dr. Sonja Salmon, associate professor of textile engineering at NC State’s Wilson College of Textiles described as a “complicated space,” due to potential misunderstandings related to the various stages of a textile’s decomposition.

The first step, Salmon said, is deconstruction. This is where a textile product is taken apart. The next step is disintegration, which is where a textile is physically broken apart into smaller microscopic fragments. The last is degradation, which refers to a chemical conversion of a larger or more complex chemical structure into simpler chemical structures. A sub-group of degradation, she added, is biodegradation, where the remaining particles go through a chemical conversion into energy that can be consumed.

“When you eat something, you are biodegrading it,” she said, “and those layers are very important when we start talking about polyester or other acrylics.”

California state law, for example, has strict rules related to the use of the word “biodegradation” in connection with any polyester product. California law SB 567 prohibits any plastic product sold within the state to be labeled as “biodegradable,” “degradable,” or “decomposable,” or any form of those terms.

Sustainable synthetics

The makers of CiCLO® additive technology, a new fiber option in the textile industry supply chain, have taken that guideline to heart as they bring a new, more sustainable synthetic fiber technology to market. CiCLO chemistry is added to polymers during the extrusion process, which helps fabrics, such as polyester, break down in a way that’s similar to wool at the end of a product’s life cycle. According to materials from Parkdale Mills, which is marketing the new fiber to the textile industry, the additive technology accelerates the speed at which a synthetic fiber biodegrades in the ocean or a landfill.

CiCLO is a product of California-based Intrinsic Textiles Group LLC, which was formed to develop and commercialize sustainable, closed loop solutions for textiles. According to Cheryl Smyre, brand manager and director of advanced materials at Parkdale, apparel manufacturers can easily integrate the technology into their supply chain.

She adds that brands in the performance sector are looking for ways to manufacture apparel made from synthetic fibers less polluting, without losing the performance strengths of synthetics such as polyester and nylon.

“Extensive testing by reliable third-party laboratories over a number of years has proven that CiCLO technology is effective at reducing synthetic fiber accumulation in landfills and microfiber pollution in the oceans,” Smyre said. “At the same time, products made from CiCLO additive polyester can be washed and cared for just as you would any other polyester apparel item.”

She adds that CiCLO fibers and yarns can play a role in reducing the impact of textile waste in landfills and synthetic microfibers in the oceans generated by the high volumes of Personal Protective Equipment (PPE) that will be used as the world fights the COVID-19 pandemic.

Plant-based performance

Other companies in the outdoor apparel and gear sector that are using biomaterials to replace or supplement synthetics include NEMO Equipment and Reima USA Heiberg/Beringer. NEMO is a camping gear brand that sells sleeping bags and tents, among other products.

Currently NEMO is looking at milkweed as a biomimetic model for plant-based insulation. Milkweed is an American wildflower that produces a fluffy material that has many of the same properties as down. The fluff attached to milkweed seeds is buoyant and very warm. In the past it’s been used to stuff mattresses and pillows, as well as line winter clothing and footwear. It was also used during WWII as the stuffing for life jackets.

Reima USA Heiberg/Beringer has introduced a winter jacket made from what they describe as a “heat-storing coffee bean shimmer fabric.” Reima is a leading premium performance wear brand for children. At Winter Outdoor Retailer they showcased a jacket made in part with ground coffee beans. Carbonized coffee bean particles are mixed in the polymer with polyester and add what Reima says is rapid heat storage and “a gorgeous sheen.”

Other companies that serve the outdoor industry are also looking for ways to replace plastics with biomaterials. Costa Sunglasses, based in Dayton Beach, Fla., manufactures a line of high-end sunglasses with frames made from bio-resins derived from castor bean oil, which has a smaller overall carbon footprint than plastic. The company says the frames are designed to be durable, lightweight, and hold shape under harsh conditions.

All of these developments, which are taking place in textile labs around the globe, reflect a trend on the rise, said Beringer. Most are driven by a desire to improve the sustainability quotient of the apparel and gear that brands are selling to the world. And those efforts are needed now more than ever.

Glenna B. Musante is a freelance writer who specializes in the textile industry.

Find the article here: Advanced Textile Source

Keep Your Chill With New Shirts by Atlas Menswear

Men with an athletic physique often struggle to find dress shirts and other clothing that fits their muscular build, and apparel designer Atlas Menswear aims to change that.

Men with an athletic physique often struggle to find dress shirts and other clothing that fits their muscular build, and apparel designer Atlas Menswear aims to change that.

Atlas is bringing strength to style with a new line of Competitor Series dress shirts that feature a super soft stretchy fabric that allows maximum movement and comfort.

Exclusively made with a muscle-fit design that refined over many months of measuring and fitting sessions with athletic men, the Competitor Series shirts accommodate strong upper body musculature with freedom of movement and breathability from the brrr° fabric.

The stylish shirts also feature a “Below-the-Belt” button that creates a clean line and polished look when the shirts are worn untucked.

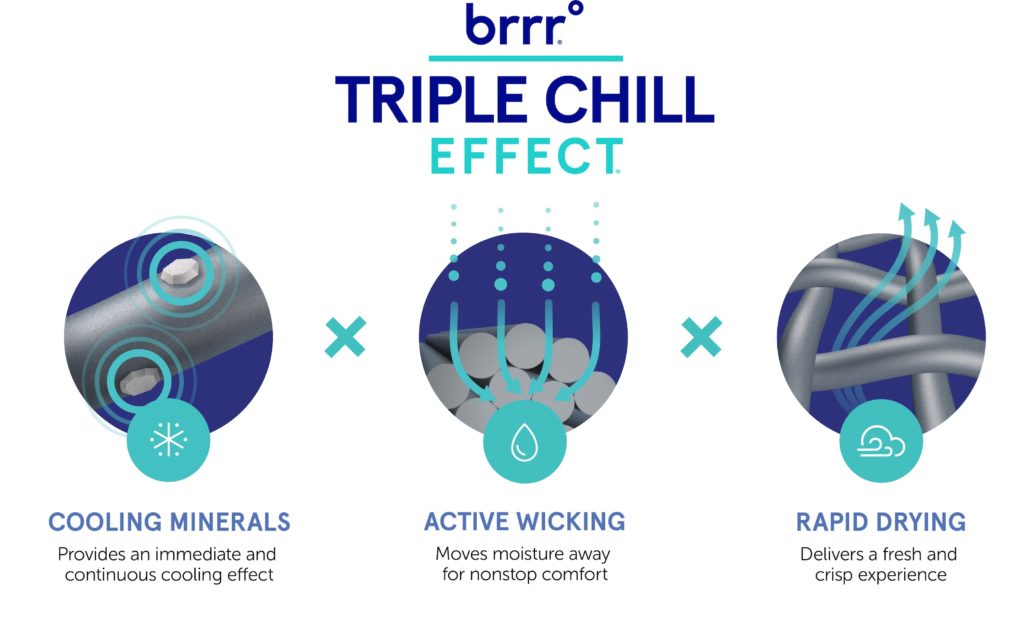

We’re proud to work with Atlas to bring cooling performance technology to their Competitor Series line of shirts. brrr°’s natural cooling minerals, active wicking, and rapid drying technologies work together to create a “Triple Chill Effect” that instantly and continuously draws heat and moisture away from the skin.

You can find the Atlas Menswear Competitor Series here.

What Women Want: Undergarments That Keep Them Cooler & More Comfortable

The women’s undergarments industry is going through radical changes, and much of it revolves around functionality and comfort.

Startup brands such as True & Co., ThirdLove and Shapermint are taking cues from direct-to-consumer retailers like Warby Parker and have launched growing businesses driven by internet and social media campaigns aimed at convincing women that their products are the perfect blend of comfort, functionality, and design.

One innovation is personalized fit quizzes that help women figure out what size to buy, and which products will support their unique body style the best. This is key because as many as 80% of women may be wearing the wrong size bra, in part because sizes can vary drastically from brand to brand, according to a survey by Victoria’s Secret. Most online-only brands offer free returns or exchanges for items that don’t fit.

Modern women prize functionality and comfort, and Millennials are drastically changing the bra buying landscape by shopping online more often than Gen X and Boomer women. Millennials are also more likely to wear sports bra styles, according to research by NPD Group.

Wireless bras, bralettes, racerback bras and bras inspired by athletic apparel are getting more sophisticated, with support technology come from performance fabrics and the structure of the garment so it doesn’t dig into the skin or chafe the way bras did for generations.

Designers and manufacturers of bras, underwear, shapewear, slip shorts and other undergarments are also using more stretchy, breathable materials that help keep women dry and more comfortable from dawn until bedtime.

These materials also make it possible for women with active lifestyles to wear the same bras and undergarments from the office to the gym, and most of the garments can be machine washed on gentle cycle with a simple mesh bag for easy maintenance.

We hope to see more retailers push even further by incorporating cooling fabric into their next generation of bras, underwear and other undergarments. brrr°’s patented technology uses a special blend of natural cooling minerals plus active wicking and rapid drying to create a “Triple Chill Effect” that won’t ever fade or wash out. brrr° fabrics are independently lab tested to prove the cooling properties, and they consistently outperform other brands.

Find out how brrr° cooling technology take undergarments to the next level. You can reach us here.

Say Goodbye to Sweaty Feet with Bigfoot Socks Featuring brrr°

Feet have never been so lucky.

Feet have never been so lucky.

Bigfoot Sock Co. is using brrr° cooling technology in a new line of performance socks that draw heat and moisture away from the skin.

brrr° combines natural cooling minerals, active wicking, and rapid drying to create a “Triple Chill Effect” that helps keep your feet more comfortable all day long.

Bigfoot socks are available in numerous colors, and no-show and loafer styles for complete flexibility in your footwear game.

You can find them here at Sock Harbor.

We Love Southern Tide’s Cooling Dresses

Hello, ladies!

Beat the heat this summer with this new line of casual dresses by Southern Tide featuring brrr° performance cooling technology.

The fabric has brrr° natural cooling minerals, plus active wicking and rapid drying technologies to instantly and continuously draw heat and moisture away from the skin. The brrr° “Triple Chill Effect” helps keep you comfortable and confident all day long.

Southern Tide’s Kamryn Intercoastal Shirt Dress is a casual performance popover that will help you feel fresh and breezy. The collar features a contrast gingham print lining, with cuffed short sleeves and a snap tab detail, and pockets for carrying essentials.

The Kamryn Intercoastal Gingham Shirt Dress has an easy pull-on design, bias-cut back placket and welt hand pockets for your phone and lipstick.

Both dresses are machine washable for low maintenance care no matter where life takes you.

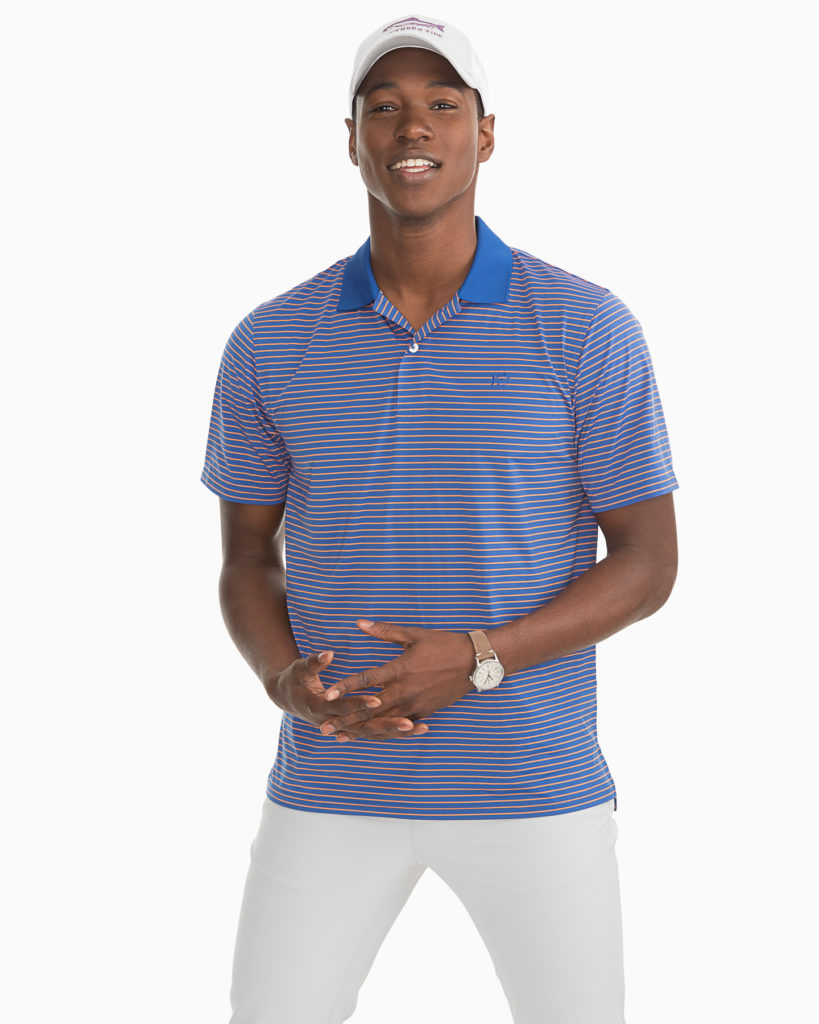

Hooray for Southern Tide’s brrr° Cooling Polos

Casual summer looks just got even cooler with a stylish line of men’s performance polo shirts by Southern Tide that feature brrr° cooling technology.

Casual summer looks just got even cooler with a stylish line of men’s performance polo shirts by Southern Tide that feature brrr° cooling technology.

The fabric combines brrr° natural cooling minerals, active wicking and rapid drying technologies that work together to create a “Triple Chill Effect” that keeps you comfortable and confident all day long.

Whether golfing, meeting friends for tennis or enjoying a backyard barbecue, these Southern Tide polos work hard to instantly and continuously draw heat and moisture away from the skin.

Available in a variety of solids and stripes, the polos have stretch for maximum comfort and easy movement.

Our Commitment to You During COVID-19

The global coronavirus pandemic is truly an unprecedented situation that is affecting our families, our businesses and our way of life. Our thoughts go out to those who are sick or directly impacted by the virus and we extend our heartfelt wishes for a full recovery.

We are focused on the health and safety of our brrr° family, and all of our team members in the US and Taiwan have been encouraged to work remotely, communicate with customers through digital channels, and minimize travel and conference attendance. This is an easy transition for our highly mobile and sophisticated team, and we continue to deliver the highest levels of service as we practice social distancing.

Although we are in uncharted territory, our commitment to your success is stronger than ever. Our factories are operational, and our supply chain partners are undeterred by current production restrictions. We are confident that we can continue to deliver our proprietary cooling yarns and fabrics on time and with the highest quality.

We have an amazing team at brrr° and we are here for you. While we are facing some significant headwinds, we are confident that we will overcome these obstacles and be better for it.

If there are any ways brrr° can help you or your team with our technology or services, please let me know at mckolb [@] brrr.com.

Sincerely,

Mary-Cathryn Kolb

Founder and CEO, brrr°

Talking About Cooling Comfort at Trade Show Trifecta

Advances in cooling performance technology were hot topics on the January trade show circuit, and brrr° was delighted to be front and center in those conversations.

We kicked off the month with the Texworld show in New York, where we debuted our new pop art campaign that highlights the cooling comfort of brrr° technology. We create a Triple Chill Effect by combining the powers of natural cooling minerals, active wicking and rapid drying for a crisp, fresh experience that lasts all day.

At the PGA Show 2020 in Orlando, our customer Southern Tide had a beautiful display of shirts and other apparel made with brrr° cooling technology. Attendees loved the cool-to-the-touch sensation of the button-downs, shorts, and polos.

We wrapped up January with a strong appearance at the Outdoor Retailer Snow Show in Denver, where the coolest new apparel and gear are on display.

Staying cool and comfortable all year long is essential, even in chilly temperatures. The wicking and drying capabilities of brrr° fabric help you perform better and feel your best during winter activities such as skiing, snowboarding, hunting, running or whatever else you have planned.

Although we’ve been working hard, we’re not working up a sweat as we kick-off 2020. You know why. #brrrcool

Amplifying the Cooling Effects of brrr°

brrr comprises the Triple Chill Effect to cool, wick and dry

Busy, active lifestyles coupled with the ongoing climate crisis that continues to dominate the headlines, is driving the demand for innovative cooling solutions in all aspects of our daily lives. And, as textiles are omnipresent, they naturally make a great vehicle for administering such solutions.

Feeling cool and comfortable in whatever activity we’re doing heightens our overall wellbeing and performance. So, with this in mind, the company brrr° set out to explore how textiles can be enhanced to meet this need.

Founded in 2014 by Mary-Cathryn Kolb, a retail industry expert who has worked for apparel brands such as Spanx and Von Dutch, brrr° developed a proprietary cooling fabric technology that can be integrated into any existing fabric to bring immediate and continuous cooling. To do so, a secret blend of natural minerals are embedded into the yarn itself to become a permanent part of the fabric that, unlike coatings or sprays, doesn’t wash out over time.

Explaining the process in more detail, Mary Jane Credeur, a spokesperson for brrr°, says: “We begin by adding our secret blend of minerals into the nylon or polyester pellets, which are extruded as yarn that is then turned into fabric. Our cooling minerals are permanent and part of the structure of the yarn. Under a microscope you can actually see the little mineral speckles.”

The cooling feature is combined with wicking and rapid drying technology to form what brrr° calls the Triple Chill Effect. For instance, brrr° nylon and brrr° polyester are described as ‘cool to the touch’ with more chill than comparable competitors, while the wicking technology moves moisture away from the skin, for ‘non-stop comfort’, and the quick drying capability rapidly releases moisture into the air, cooling the fabric and providing a ‘fresh and crisp’ experience.

To realise the potential of the technology, brrr° has several ‘go-to’ mill partners in Taiwan who are considered a part of its R&D team. All brrr° products are tested by independent labs to prove the effectiveness. For instance, tests conducted last year by Intertek Testing Services found that brrr° nylon and polyester fabrics consistently outperformed numerous other comparable products in lab tests that measure Qmax (cool to the touch feeling), wicking and dry time.

“For years, a lot of the apparel manufacturers claimed that their products were cooling but they were just wicking, they didn’t actually draw away heat per se. Some products you have to get wet before they cool, and that’s not very practical. The science behind it, that’s our pedigree. It’s not just a gimmick that’s going to wear out over time like sprays or coatings do,” says Credeur.

END USES

An obvious application for the technology would be activewear and outdoor wear, where users are prone to working up a sweat, but Credeur says the end uses span various elements of a consumer’s wardrobe and lifestyle. And, as an ingredient brand, brrr° has garnered interest from various retailers and manufacturers looking to integrate the cooling fabric technology into their collections.

Credeur says: “A lot of our launches have been casual polo shirts, so not just outdoor wear, but also casual weekend wear, office wear, dress shirts, linings of suits, and undergarments – we’re in talks with a few co-branded partners. Plus, we have a new line launching with CAT Workwear from Caterpillar – an outdoor, rugged apparel line.”

Home textiles are another key end use, particularly bed sheets. “There tends to be more demand around things you actually touch and interact with,” says Credeur. “Sheets are an obvious one, as memory foam mattresses make you sweat a little bit more. Women who are menopausal or pre-menopausal tend to appreciate that a lot. We think that someday we’ll get some demand from sofa material coverings and fabric for upholstery. And we have been in talks with auto manufacturers for car seat materials.”

The company has also integrated its cooling fabric technology into denim, with successful results. It states on AATCC’s fashion blog that independent lab tests show that brrr° denim feels 38% cooler to the touch than comparable traditional denim, dries up to 47% faster and wicks 2.5 times better.

And aside from this, brrr° has taken steps in the energy harvesting field, having received a patent using piezoelectrics technology. “Somewhere down the road you may be able to stick a device in your back pocket and charge it from your clothing,” says Credeur, who adds that the company hasn’t actioned the patent just yet but considers it a ‘cool technology to explore’.

ENVIRONMENTAL EDGE

Micro minerals of any kind are bound to raise questions over their safety to human health and the environment, but Credeur assures that the minerals used by brrr° are safe. “Our proprietary mineral blend is not reactive and absorbed by skin at all,” says Credeur. “It’s an organic material but it’s combined with a man-made one, blending into this master batch as it gets produced. Its behaviour is no different to any other polyester or nylon or base material.”

The technology has also found itself being used in recycled fabrics, as the textile industry continues to boost its sustainability profile. “We do have GRS [Global Recycle Standard] certified suppliers of recycled yarns,” says Credeur. “We buy yarn that has recycled material in it and integrate brrr° technology into it as part of the manufacturing process. There’s a lot of talk and interest in recycled material and, with some brands that are very forward thinking, they tend to be hungrier for that technology. They’re also willing to pay more as it’s a premium product. Some brands are not quite there yet, and you have to respect that as well. It’s what the customer wants and what the market wants, especially the younger generations who tend to be curious about where their products come from.”

NEXT STEPS

Credeur reveals that brrr° is planning to enhance the technology to increase the surface area of the minerals effectively and amplify the cooling effects. “We’re exploring some new dispersion technologies, how we blend the minerals, and how we integrate the minerals with the actual yarn in the first place,” she says. “If you can increase the surface area, you can directly improve the effect of the cooling minerals.”

New products based on this technology will be rolled out this year, in line with the company’s fifth anniversary. “We’re really starting to get traction with a couple of national and international retailers,” says Credeur. “Down the road there will be additional hiring and additional fundraising to grow.”

This is particularly important as Credeur says there are educational hurdles to overcome with brrr° technology to explain to retailers and consumers how and why it’s better than previous generation technologies that claimed to be cooling but were ‘really just wicking’.

“The challenge is being able to capture the attention and articulate the benefits quickly in a way that people can understand how it’s different and why it’s different, and how the science works,” she says.

Credeur adds: “It’s about getting our name out there. People want clothing that does something more for them – they want comfort, they want it to wick and to dry quickly. We see ourselves as part of the solution – the planet is not getting any cooler.”

To find out more about brrr° Triple Chill Effect technology, visit https://brrr.com/

Have your say. Tweet and follow us @WTiNcomment

Source: WTIN

Innovate or die: Make R&D a priority even when budgets are tight

Atlanta Business Chronicle Leadership Trust By Mary-Cathryn Kolb , Founder CEO at brrrº

The early years of most startups are lean and mean, with modest funding that probably came from friends, family, angel investors or good old bootstrapping.

Budgets are extremely tight, which means the office furniture is probably more shabby than chic. Everyone wears multiple hats and works long hours, and there is an obsession with stretching every single dollar as far as possible. That means printing on both sides of the paper and sending product samples with postage stamps instead of overnight express.

However you choose to scrimp and save, there is one budget line item that you should protect and grow no matter what: research and development. R&D should be one of your largest expenses because it is the lifeblood of a young company.

The innovation that comes from a robust R&D program gives you a competitive edge and helps improve the products and services that first inspired you to start your business. Simply put, R&D can make or break a startup.

If you cut back on R&D, you risk losing your competitive edge. Or worse, you could become irrelevant in a hyper-crowded marketplace. I learned that the hard way in my early years as an entrepreneur.

After successfully launching my company and receiving lots of press coverage and orders from major retailers, we got sucked into the siren song of the fashion world and started focusing too much on trending colors, hemlines and garment styles.

One day I had this lightning-bolt realization that we were putting our mission of developing better cooling fabric technology in the back seat and letting fashion take the front seat. I decided to do the unthinkable: I turned down orders from major retailers. I cut other budgets so I could shift more money back to R&D. I pivoted back to focusing on innovation.

In my experience, focusing on what makes your company innovative rather than keeping up with the latest trends is a great way to increase your intellectual property. In a more innovation-focused atmosphere, you’ll likely find — as I did — that your team is more creative and better able to come up with improved techniques. That can have a ripple effect, improving your relationship with your partners and vendors who can act as strong advocates for your brand.

People thought I was nuts, but it was absolutely the right thing to do — and sales numbers prove it. But none of this would have been possible if we had stayed the course and let ourselves stray further from what we originally set out to do. You have to recognize those lightning-bolt moments as huge opportunities to steer your company in the right direction.

People often ask me to share advice about starting a company, and there are so many important things to say about leadership, raising capital and having grit.

But one of the most valuable pieces of wisdom I can share is that you have to protect your R&D budget no matter what. Make it a sacred cow, and increase it steadily over time. To be successful, it’s as simple as this: Innovate or die.